MoDTC in Lubricants- Enhancing Engine Performance with Advanced Chemistry

MoDTC in Lubricants: Enhancing Engine Performance with Advanced Chemistry

The complexity of modern engine technology has increased the demand for advanced lubricants that not only ensure smooth operation but also enhance performance and longevity. One of the key additives in contemporary engine oils is Molybdenum Dialkyldithiocarbamate (MoDTC). This chemical compound plays a crucial role in optimizing engine performance through its unique properties and interactions. In this article, we will explore MoDTC’s chemistry, its benefits in lubricants, and its impact on engine performance and efficiency.

Understanding MoDTC

Molybdenum Dialkyldithiocarbamate (MoDTC) is a type of organomolybdenum compound that functions as a friction modifier in lubricants. MoDTC is composed of molybdenum, a transition metal known for its lubricating properties, combined with dialkyldithiocarbamate ligands. The compound is well-regarded for its ability to reduce friction and wear in engine components.

Chemical Structure and Properties

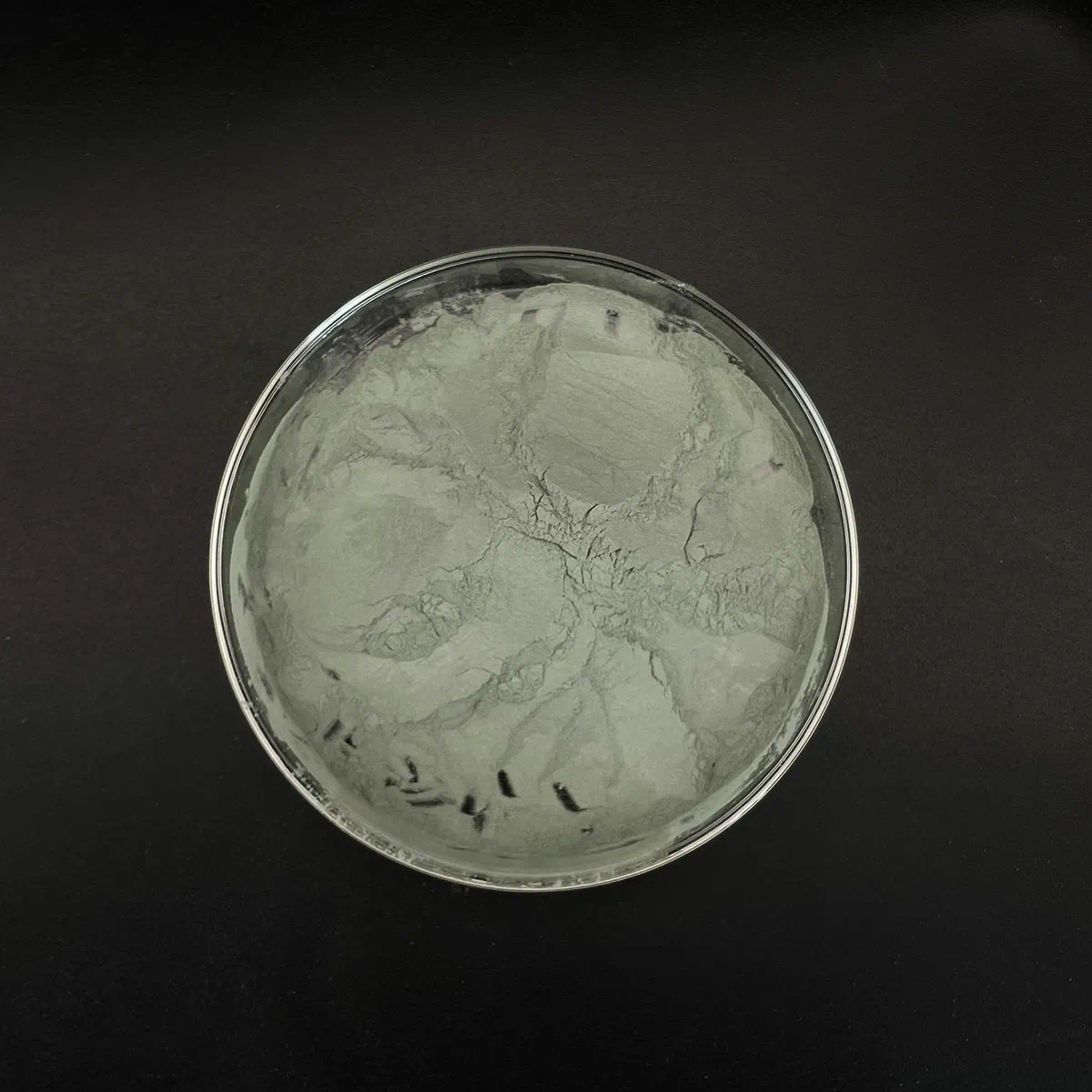

The chemical structure of MoDTC includes a central molybdenum atom bonded to two dialkyldithiocarbamate ligands. The dialkyldithiocarbamate groups contain sulfur, carbon, and nitrogen, which contribute to the compound’s effectiveness as a friction modifier. MoDTC’s molecular configuration allows it to form a protective film on metal surfaces, reducing friction and wear.

The key properties of MoDTC include:

– Anti-wear Protection: MoDTC forms a strong boundary layer on metal surfaces, providing exceptional anti-wear protection.

– Friction Reduction: The compound helps to reduce friction between engine components, which improves fuel efficiency and reduces energy consumption.

– Corrosion Inhibition: MoDTC also offers corrosion protection, safeguarding engine parts from oxidative damage.

Benefits of MoDTC in Engine Oils

The inclusion of MoDTC in engine oils brings several benefits that contribute to improved engine performance and longevity.

Enhanced Wear Protection

One of the primary advantages of MoDTC Hpmc Hydroxypropyl Methylcellulose is its ability to provide superior wear protection. Engine components experience significant stress and friction, leading to wear over time. MoDTC creates a lubricating film on the metal surfaces, which helps to minimize direct contact and reduce wear. This protective layer is especially beneficial in high-stress conditions, such as high temperatures and heavy loads.

Improved Fuel Efficiency

By reducing friction between engine parts, MoDTC contributes to better fuel efficiency. Lower friction means that the engine operates more smoothly, requiring less energy to perform the same work. This can lead to a noticeable improvement in fuel economy, which is beneficial both for the environment and for vehicle owners seeking to reduce operating costs.

Enhanced Engine Performance

MoDTC’s ability to reduce friction and wear directly impacts overall engine performance. With less friction, the engine can operate more efficiently, delivering better power output and responsiveness. This is particularly important in high-performance engines where optimal efficiency and performance are crucial.

Longer Oil Life

Engine oils containing MoDTC typically experience extended service life. The compound helps to maintain the oil’s viscosity and effectiveness over time, reducing the need for frequent oil changes. This not only lowers maintenance costs but also contributes to better environmental sustainability by reducing the frequency of oil disposal.

Mechanisms of MoDTC Action

To understand how MoDTC works within engine oils, it is important to delve into its mechanisms of action.

Formation of a Protective Film

MoDTC forms a protective film on metal surfaces through a process called adsorption. The sulfur atoms in the dialkyldithiocarbamate ligands interact with the metal surfaces, creating a thin but durable layer that reduces friction and wear. This film acts as a barrier between moving parts, preventing direct metal-to-metal contact.

Reaction with Metal Surfaces

The molybdenum in MoDTC reacts with metal surfaces to form a molybdenum disulfide layer. This layer has excellent lubricating properties and contributes to reduced friction and wear. The reaction is particularly effective under high-pressure and high-temperature conditions, making MoDTC suitable for modern high-performance engines.

Compatibility with Other Additives

MoDTC is compatible with a wide range of other additives commonly used in engine oils, such as detergents and dispersants. This compatibility allows for the formulation of multi-functional oils that offer comprehensive protection and performance benefits. The synergistic effects of MoDTC with other additives enhance the overall effectiveness of the engine oil.

Applications and Industry Trends

MoDTC has found widespread application in various types of engine oils, including those used in passenger vehicles, commercial trucks, and high-performance sports cars. The compound is especially valuable in engines that operate under extreme conditions, such as high temperatures and heavy loads.

Passenger Vehicles

In passenger vehicles, MoDTC is used to improve fuel efficiency and engine performance. The compound’s ability to reduce friction and wear contributes to smoother engine operation and longer oil life. As vehicle manufacturers continue to focus on improving fuel economy and reducing emissions, the use of MoDTC in engine oils is likely to become even more prevalent.

Commercial Vehicles

For commercial vehicles, which often experience heavy-duty operation and long service intervals, MoDTC provides essential protection and performance benefits. The compound helps to reduce engine wear and extend oil life, which is crucial for maintaining the reliability and efficiency of commercial fleets.

High-Performance Engines

High-performance engines, such as those found in sports cars and racing vehicles, benefit significantly from MoDTC. The compound’s ability to operate effectively under high-stress conditions enhances engine performance and durability. Racing teams and performance car manufacturers often use specialized engine oils containing MoDTC to achieve optimal results.

Future Directions and Research

As engine technology continues to evolve, the role of MoDTC in lubricants will likely undergo further advancements. Ongoing research and development efforts are focused on enhancing the performance of MoDTC and exploring new applications.

Development of New Formulations

Researchers are working on developing new formulations of MoDTC that offer even greater benefits in terms of friction reduction, wear protection, and fuel efficiency. These advancements aim to address the evolving needs of modern engines and improve the overall performance of engine oils.

Environmental Considerations

There is also growing interest in developing environmentally friendly formulations of MoDTC. This includes exploring alternative materials and methods that reduce the environmental impact of lubricant additives. The goal is to create products that meet performance standards while also supporting sustainability initiatives.

Integration with Emerging Technologies

As new technologies such as electric and hybrid vehicles become more prevalent, the role of MoDTC may need to be adapted. Research is underway to understand how MoDTC can be optimized for use in these emerging vehicle types and to ensure that it continues to provide value in a changing automotive landscape.

Conclusion

Molybdenum Dialkyldithiocarbamate (MoDTC) is a pivotal component in modern engine oils, offering significant benefits in terms of friction reduction, wear protection, and overall engine performance. Its advanced chemistry enables it to form protective films on metal surfaces, reduce friction, and extend oil life, making it an essential additive for both passenger and commercial vehicles.

As engine technology continues to advance, the role of MoDTC will likely evolve, with ongoing research and development focused on enhancing its performance and exploring new applications. By leveraging the benefits of MoDTC, engine oils can continue to meet the demanding requirements of modern engines and contribute to improved efficiency, performance, and sustainability.

https://supplychaininterview.com/